| This topic discusses: | Links to related topics: |

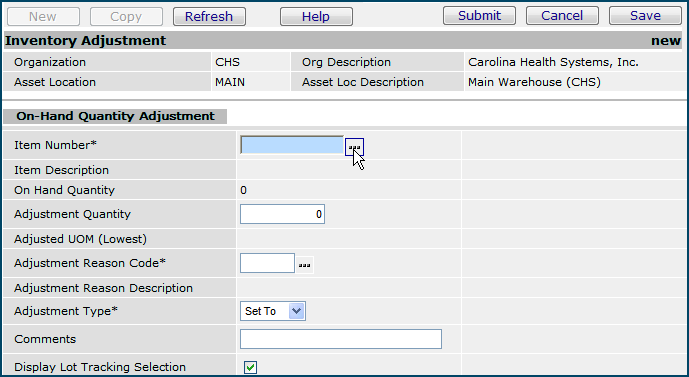

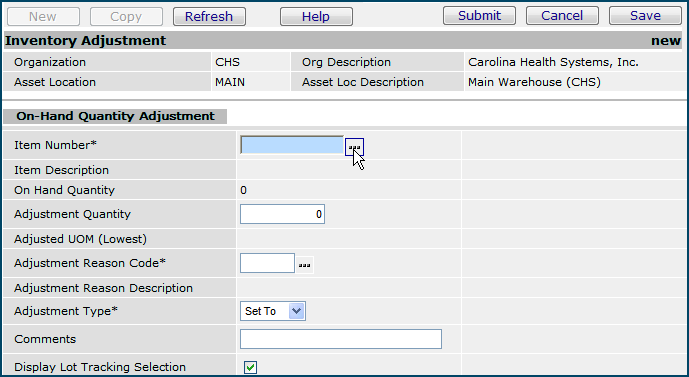

From time to time, you may need to adjust the on-hand quantity of an inventory item. Supply Chain handles inventory adjustments automatically, for example, when items are returned to inventory from a department, or returned from inventory to a vendor. However, some situations -- such as discovering items stored in the wrong location -- require manual adjustments of on-hand quantity. Also, you may wish to set the initial on-hand quantity for new items in an inventory.

If an item is reusable, eventually, it will wear out, and will need to be replaced. When a reusable item can no longer be issued, the on-hand quantity of the item can be reduced using manual adjustment.

To access organization, department, or asset location data, the organization, department, or asset location must be included in your data profile. Additionally, for any asset location, you must have permission to maintain the asset location record, including manual inventory adjustments and setting up lot tracking. See "Restricting Users from Editing Asset Location Records."

The application makes the adjustment for the lowest unit of measure of the item as shown in the field Adjusted UOM (Lowest).

Lot Tracking

When you adjust on-hand quantity from the Warehousing contents, the system

completes the Lot Tracking field after you enter an Item No.

If lot tracking is enabled for the item, this field is selected automatically.

Otherwise, the field is blank. See the discussion of Lot

Tracking below.

You can also perform manual inventory adjustments from the Materials Inventory menu, as follows:

Lot tracking allows you to keep records of lot numbers, serial numbers, and/or expiration dates for inventory items. You associate lot-tracking information with patient data when an item is issued. Lot information and patient data can be entered in the system during activities -- such as receiving -- that change the on-hand quantity of an item. Manual inventory adjustment is another such activity. (See Track Lot Information and Patient Information for Items for details.)

For each asset location, lot tracking must be "switched on" and the type of lot information to be tracked must be identified. Items in an asset location use the lot tracking settings specified when the items were assigned, but you can override the settings, if you wish. You can turn lot tracking "off" for any item, and you can select the information -- lot number, serial number, expiration date, all three, or combinations -- that is recorded for each item. (Your user profile permissions must be set for you to turn on lot tracking for an item or asset location.)

The lot tracking setting is visible for items whose inventory you are adjusting. You can adjust an item's inventory from either of two menus:

If your user profile is set up to allow you to enter lot and patient information, you can do so when you adjust an item's inventory. To enter lot information, use the Item Inventory list menu. Since you can also adjust the inventory from the Item Inventory list, if you think that you will also be entering lot information for an item, it may be best to do everything from the Item menu, instead of using the Warehousing menu.

Copyright © 2023 by Premier Inc. All rights reserved.