Purchase orders created and processed by the system can be separated in several ways. One way to separate POs is by department. For example, an individual department may need exclusive purchase orders for its items. Or, a vendor may require each department at your site to use a separate PO when ordering items. In either case, you will want to create POs that contain only supplies requested by each specific department.

Another category that you can use to separate POs is item type. With separate POs by item type, you order stock items on one PO, and order non-stock (and non-file) items on a different PO. Item type can be used for separating POs if required by either the organization or the vendor.

Finally, your site may be organized so that you create separate POs for each of your buyers. You assign a primary buyer to an organization, and you may also specify a second buyer for stock items and a third buyer for non-stock/non-file items. You may assign a buyer to a vendor, asset location, or department. These assignments can be used to group POs for each particular buyer.

Direct Delivery behaves like a stockless environment, and is key to organizations that use a JIT (just-in-time) supply strategy. Requisitions opened as direct delivery are not filled from inventory, but are placed on purchase orders to be delivered directly to the requesting department. If your site maintains inventories, direct delivery purchase orders treat stock items as though they are non-stock items. Even if you have enough quantity of a stock item to fill a direct delivery requisition, the item is still placed on a purchase order.

You can specify direct delivery whether or not the department (or the vendor) requires an exclusive, separate PO for its items. However, the relationship between direct delivery and separating POs by department (or vendor) is close. Additionally, the type of item that you order can be a factor. So, this section discusses both direct delivery POs and separate POs by department or item type. Notes about separating POs according to buyer are included at the end of this section.

The online document "Using direct delivery in a JIT environment" contains examples of JIT processing with direct delivery.

To access organization, department, or asset location data, the organization, department, or asset location must be included in your data profile. Additionally, for any asset location, you must have permission to maintain the asset location record. See "Restricting Users from Editing Asset Location Records."

The role objects that control access to the required functions are "Purchasing" and "DeptReq," minimally set to View.

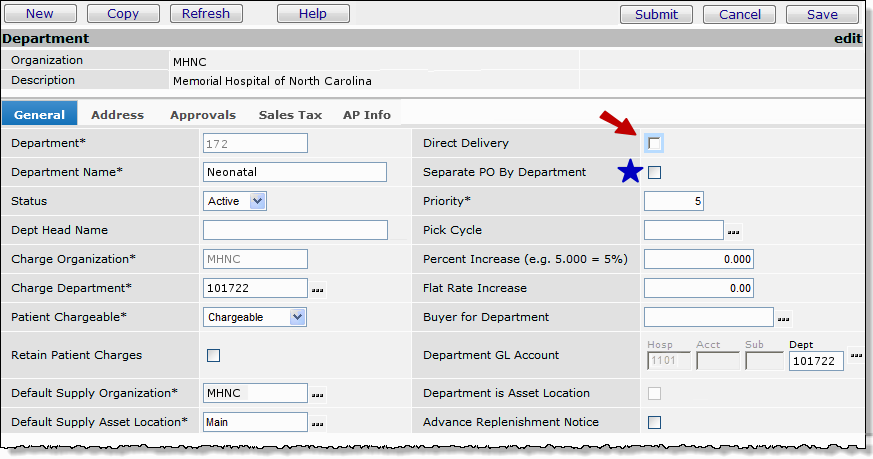

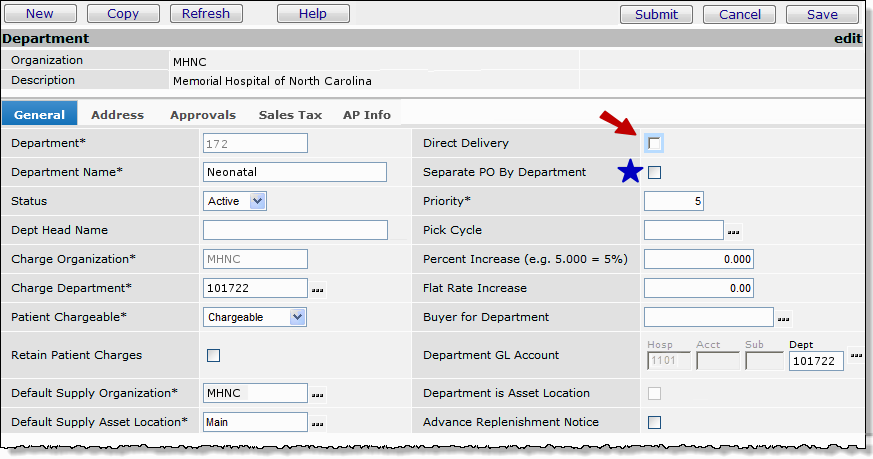

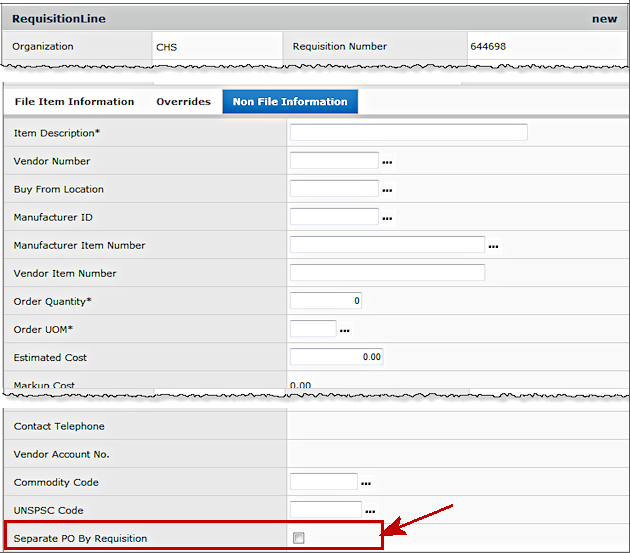

You can specify a department or a vendor buy-from location as direct delivery. You use the Direct Delivery check box on the Department panel to set direct delivery for a department (Figure 1, next to the red arrow). Similarly, the Direct Delivery check box on the Vendor Buy-From Location panel sets direct delivery for a vendor buy-from location (Figure 2, next to the red arrow). (We will discuss the field next to the blue stars and the gold star below.)

When direct delivery is set for a department, all requisition lines for that department default to direct delivery. (If you wish, though, you can override the Direct Delivery field on the requisition line when you create a requisition.) Items on direct delivery requisitions are placed on a direct-delivery purchase order when the requisition is approved. Best packaging is ignored, unless the units of measure are evenly convertible. All item types (stock, non-stock and non-file) are placed on the purchase order, and require a Deliver-To Department. Requests for the same item for different direct-delivery departments are placed on the same purchase order. However, each department's request will be on a separate purchase order line and the department information is included on the printed purchase order.

A given vendor buy-from location may require direct delivery for all departments, although other vendors may not require direct delivery. For this reason, you can set a vendor buy-from location as direct delivery, but not set individual departments as direct delivery. When a vendor buy-from location is set to direct delivery, all requisition lines for that vendor buy-from location default to direct delivery. The requested items are placed on a direct delivery purchase order, and best packaging is ignored, unless it is evenly convertible. The system puts requests for the same item for different departments on the same purchase order. However, each department's request is on a separate line and department information is included on the printed purchase order. All stock and non-file item lines must have a Deliver-To Department specified. The Backorder panel appears for non-stock items.

Notes on direct delivery requisitions:

Your site may need the option to separate purchase orders by department. A department may require its items to be listed on its own purchase orders, separate from other departments' orders. Or, a vendor may require all orders for a particular buy-from location to be separated by department, with a different purchase order for each department's requests.

To specify that a department needs its purchase orders to be separate from other departments, use the Department information panel. Select the check box for Separate PO by Department. (See the field next to the blue star in Figure 1.) To specify that a vendor requires a separate purchase order for each department, select the check box for Separate PO by Department on the Vendor Buy-From Location panel. (See the field next to the blue star in Figure 2.)

When Separate PO by Department is checked on the Vendor Buy From Location panel, the following occurs:

If a vendor buy-from location requires both "direct delivery" and "separate PO by department," requisition lines default to "direct delivery." (You can, however, override "direct delivery" on a requisition line.) When the requisition is approved, all lines marked "direct delivery" (including stock, non-stock, and non-file items) are placed on a direct delivery purchase order. The purchase order is also a "separate PO by department." Best packaging is ignored. The Ship to information shows the department address. The Deliver-To Department field for the first PO line also shows the department.

Note: The system will not create a purchase order for a vendor-designated "separate PO by department" item when an asset location itself is the requisitioning Department.

In an inter-organizational setting, if ...

then the system creates a requisition with a status of Complete, does not create a purchase order, and writes a system message.

For example, suppose asset location SPC is supplied by asset location Main. Main has a non-stock item Dust Shield in its records. SPC has Dust Shield as a stock item.

The vendor requires "separate POs by department" for Dust Shield. When SPC sends a requisition to Main for the item, with SPC as the department, the system does not create a PO, writes a system message, and completes the requisition. In this case, the requisition should have had a hospital department, other than an asset location specified.

When a department has checked the field Separate PO by Department (on the Department Information panel), the following occurs:

If a department requires both "direct delivery" and "separate PO by department," requisition lines for the department default to "direct delivery." (However, you can override "direct delivery" on a requisition line.) When the requisition is approved, all lines marked "direct delivery" are placed on a direct delivery purchase order. The purchase order is also a "separate PO by department." Best packaging is ignored. The Deliver-To Department value defaults to the Ship To Location, and cannot be changed.

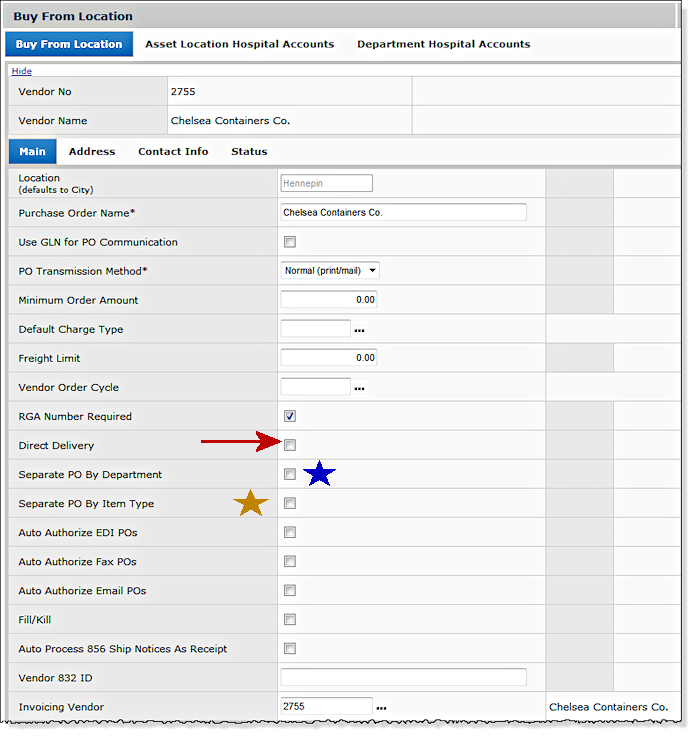

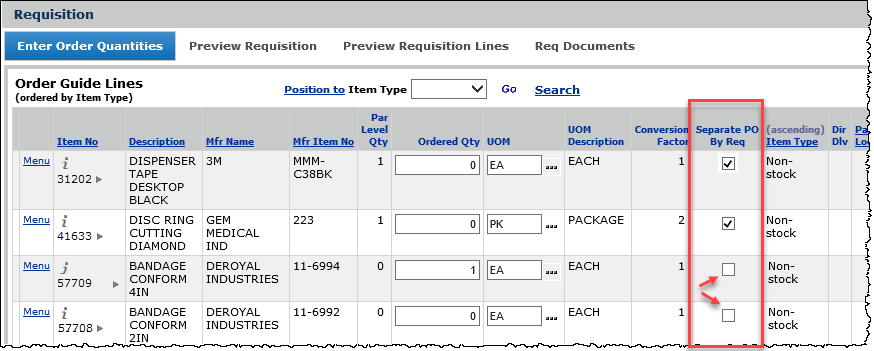

For purchase orders generated from requisitions, the field Separate PO by Requisition can be selected on the requisition line (Figure 3). When the field is selected, the requisition line is entered on a separate PO for the vendor. You can select this field on a non-file, non-stock, or direct delivery requisition line.

For requisition imports, Materials Management can generate separate POs using the Separate PO by Requisition field on the requisition import template line. When the Separate PO by Requisition field is set for a line, the system does not combine like items across multiple requisitions, but generates separate POs for each requisition number, including requisitions created externally and imported. (See Requisition Import and Replenishment of Supply-Dispensing Units.)

The requisition follows the normal process of approval and release, including approval routing, if required, for commodity code, cost, or item type. (See "Requisition Approval Processing by Cost, Commodity Code and Item Type" in the online documentation.)

In generating purchase orders for a released requisition, the system first checks to determine if any requisition lines are specified as Separate PO by Requisition.

You can move lines generated as Separate PO by Requisition from one PO to another PO, as long as the "move to" PO contains Separate PO by Requisition lines from the same requisition. If no other PO for the same requisition exists, the system creates a new PO for the moved lines.

As discussed previously, the field Separate PO by Requisition can be selected on a requisition line. When the field is selected, the requisition line is entered on a separate PO for the vendor. Additionally, an entire requisition (and all its lines) can now be designated as "separate." This feature allows separate POs at the requisition header level, and prevents lines from multiple requisitions to be combined on a purchase order. It also saves you the trouble of flagging each line that you want on a separate PO.

Details:

Below are examples:

Materials Management main Contents > Requisitioning > Requisitions > New

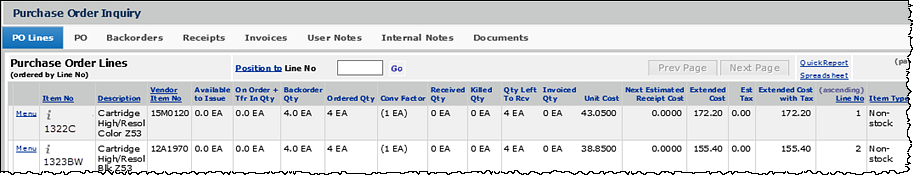

Figure 8 displays PO lines on the unauthorized PO created for the requisition above. If another requisition is created for the same vendor, it's lines will not migrate to the same PO as the PO generated using Separate PO By Requisition.

You can change the status of individual lines by editing the requisition (Figure 9) and unselecting Separate PO By Req.

The Separate PO by Requisition feature is useful with purchase orders for capital projects, especially if the purchase order also contains a Project Code. Another feature lets you specify that a GL account requires a Project Code. When a requisition line is expensed to the GL account, a Project Code must be entered for the line. See Using Project Codes with GL Accounts.

In addition, you can associate a Project Code with a Commodity Code so that a requisition can also be required to follow the approval routing circuit set up for the Commodity Code. See Requisition Approval Processing by Cost, Commodity Code and Item Type.

If a purchase order is manually created as a "separate PO by department," (the department is the Ship to Location), and the department has not specified "direct delivery," then stock items are not allowed on the PO. When a non-stock item is entered on the PO, the Department Backorder panel does not appear. The Deliver-To Department field on non-file lines defaults to the "ship to" information.

When a department, asset location, or organization requires materials tax to be calculated (i.e., the field Calculate Tax for Materials Transactions is selected for one or more of those units), ERP checks whether a tax rate has been specified on the Sales Tax tab. If so, the application uses it. If not, ERP checks other possible MM tax settings in hierarchical order until tax is found.

The order the application uses to search for a materials tax rate is the following:

- Stock items: Vendor Buy-From Location > Asset Location > Org

- Non-stock and non-file items: Vendor Buy-From Location > Department > Asset Location > Org

If tax has not been specified at any level, an error appears to tell the user that tax should be set up at the department level.

- Stock Items: Vendor Buy-From Location > Department > Asset Location > Org

- Non-stock and non-file items: Vendor Buy-From Location > Department > Asset Location > Org

- Stock items: Requisition's supplying asset location > supplying organization

- Non-stock, non-file, or direct delivery items: Primary Vendor Buy From Location > Department > Asset Location > Org

Normally, a PO created from a requisition uses best packaging as the UOM.

A field on the department record lets you change the behavior of UOMs for generated purchase orders that are separate PO by department, direct delivery, or both (direct delivery and separate PO by department).

The field is on the General tab of the department record and is called Ignore PO Best Packaging.

When the Ignore PO Best Packaging field is selected for a department, ERP uses the requisition UOM when generating an associated PO, instead of using best packaging so that the vendor has the correct UOM from the PO.

- When the field is checked, and the purchase order is separate PO by department, direct delivery, or both, the requisition passes its Ordered Quantity and UOM to the purchase order when ERP creates the PO line.

(Note: The ordered quantity must be specified in terms of the purchasing UOM on the requisition.)

- When the field is checked, but the PO is not separate PO by department, direct delivery PO, or both, ERP uses the regular best packaging logic.

Similarly, when the field is unchecked, best packaging logic is used.

If the settings for Separate PO by Department and/or Direct Delivery conflict -- for example, a vendor panel has Direct Delivery unchecked, but the department has Direct Delivery checked -- then the "checked" setting takes precedence. In other words, whenever the vendor and department settings conflict for Direct Delivery or Separate PO by Department, the panel containing a "yes" (checked) determines how purchase orders are handled.

Below are some situations with different combinations of direct delivery and separate PO by department, as they might occur in a medical center setting.

The system will not allow you to put stock items on the PO unless your department is also a direct delivery department. The system will allow you to order non-stock items, however. When you order a non-stock item and enter your department number on the Backorder panel, you will get a separate PO. (If you enter any other department number, you receive an error. ) After you enter your department number on the Backorder panel for the first item, you won't see the Backorder panel again if you order more items.

Notice that the Ship to Location and all the other ship-to information on the PO changes to your department's shipping address. The Deliver-To Department and Deliver-To Organization also change to your department and organization codes. Any lines that you enter on the PO will be shipped to your department.

My department does not use separate POs, but the Vendor Buy-From Location requires them. I'm trying to create a manual PO for a stock item.

The system will let you create the PO, but it will not be a separate PO, and any other items that you order on the PO must be stock items. Your non-stock and non-file items must be ordered from the vendor on a different PO. The ship to location for the PO with stock items is your department's supplying asset location.

I'm trying to create a PO for a non-stock (or non-file) item, and I didn't get a Backorder panel. My department uses separate POs and direct delivery.

The system doesn't require you to enter backorder information -- in this case, your department number -- so this is normal.

I created a requisition with stock, non-stock, and non-file items on it. My department uses Direct Delivery, and requires separate POs. What will the PO look like?

Because your department requires a separate PO and direct delivery, the system includes the stock, non-stock and non-file items. If a separate PO was a vendor requirement (but not required by your department), the system would also put all the items on a single PO. The Ship To Location shows your department's address.

I created a requisition with stock, non-stock, and non-file items on it. My department uses Direct Delivery. My department doesn't require separate POs, but the vendor does. What will the PO look like?

The system includes the stock, non-stock and non-file items on a PO for your department only. The Ship To Location shows your department's delivery location.

My department uses direct delivery, but not separate PO by department. Will the item lines on the PO include the total quantity for all departments, when several departments are ordering the same item?

Other departments' item lines may also occur on the PO. However, each item line matches a single department's requisition lines, even if the same item is requested by several departments. Items are shipped to each department's supplying asset location, with each department's items bundled separately (in totes) for direct delivery to the department. The Ship To Location shows the address of the asset location.

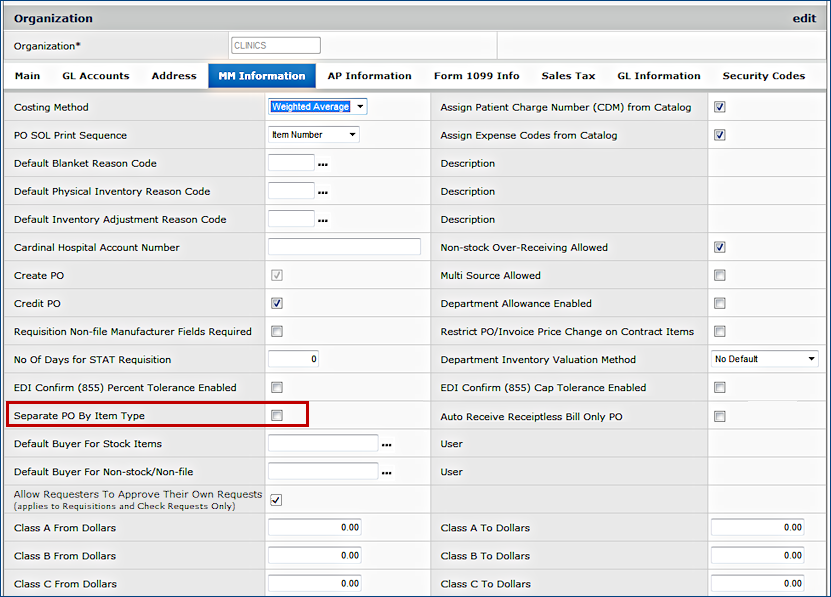

An organization or vendor may wish to separate stock items and non-stock/non-file items on purchase orders. To separate POs by item type, if required by a vendor, select the check box on the vendor Buy-From Location panel, shown in Figure 2, next to the gold star. If the organization requires separate POs by item type, select the field on the Organization panel's MM Information tab, as shown in Figure 10.

When the box is checked, stock and non-stock items for the organization or vendor are never mixed on the same purchase order.

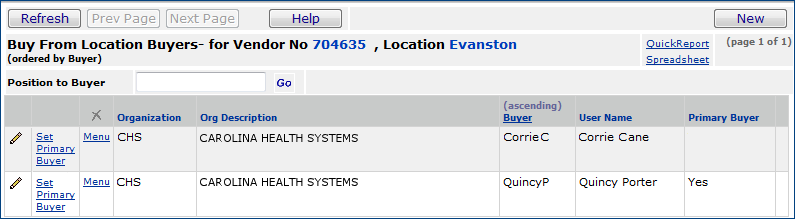

If your site has multiple buyers, you can assign buyers responsibility for different areas, and, if you wish, you can create separate purchase orders for each buyer. You can assign a buyer to...

Usually, a hospital wants a small number of purchase orders to be sent to any one vendor. However, specific buyers at a hospital may have responsibility for different areas. When a department (or vendor buy-from location) requires separate purchase orders or direct delivery, too many purchase orders could be a problem. To avoid this situation, the system uses the strategy below to assign a buyer to a purchase order if multiple buyers are listed for different areas.

When a requisition is approved and items need to be ordered, the system first looks for an open purchase order to which it can add the items. The system searches for an open PO using the following path:

The tables below describe the characteristics of requisitions and purchase orders created by setting different values (Yes=Y; No=N) for direct delivery and separate PO by department. Table 1 is for direct delivery and separate PO by department set at the department level, including item type for the Organization. Table 2 shows values when the vendor requires direct delivery and/or separate POs by department. A subset of the information in each table contains information when item type is also used to separate POs in each configuration.

| Direct Delivery | Separate PO by Dept | Separate by Item Type ORG | Separate by Item Type VENDOR | Requisitions | Purchase Orders |

| Y | N | N | N |

|

|

| Y | All of the above, except that lines go to different POs, depending on whether the items are stock or non-stock/non-file. | All of the above, except that separate POs are created for stock and non-stock/non-file items. | |||

| Y |

Lines go to different POs depending on whether items are stock or non-stock/non-file. |

Separate POs are created for stock and non-stock/non-file items for vendors who require them. | |||

| N | N | N | Processed normally. | Processed normally. | |

| Y | Item lines go to different POs, depending on whether the items are stock or non-stock/non-file. | Separate POs are created for stock and non-stock/non-file items | |||

| Y | Lines go to different POs depending on whether items are stock or non-stock/non-file. | Separate POs are created for stock and non-stock/non-file items for vendors who require separation by Item Type. | |||

| N | Y | N |

|

|

|

| Y | Stock items are subject to the response formula, and are placed on a regular PO, if an order is needed. Only stock items are on the PO. Non-stock and non-file items are not combined with stock items on POs. | Stock items are replenished using the Response Formula. If an order is needed, the system creates a separate PO for the stock items, or adds them to an existing PO. | |||

| Y | Lines go to different POs depending on whether items are stock or non-stock/non-file. | Separate POs are created for stock and non-stock/non-file items for vendors who require separation by Item Type. | |||

| Y | Y | N |

|

|

|

| Y | Requisition lines go on separate POs depending on whether the items are stock or non-stock/non-file. | Separate POs are created for stock and non-stock/non-file items. Stock items cannot be entered on the same PO as non-stock/non-file items. | |||

| Y | Requisition lines go on separate POs depending on whether the items are stock or non-stock/non-file. | Separate POs are created for stock and non-stock/non-file items. Stock items cannot be entered on the same PO as non-stock/non-file items. |

| Direct Delivery | Separate PO by Dept | Separate by Item Type ORG | Separate by Item Type VENDOR | Requisitions | Purchase Orders |

| Y | N | N |

|

|

|

| Y | All of the above, except that lines go to different POs, depending on whether the items are stock or non-stock/non-file. | All of the above, except that separate POs are created for stock and non-stock/non-file items. | |||

| Y | Lines go to different POs depending on whether items are stock or non-stock/non-file. | Separate POs are created for stock and non-stock/non-file items for vendors who require them. | |||

| N | N | N | Processed normally. | Processed normally. | |

| Y | Item lines go to different POs, depending on whether the items are stock or non-stock/non-file. | Separate POs are created for stock and non-stock/non-file items. | |||

| Y | Lines go to different POs depending on whether items are stock or non-stock/non-file. | Separate POs are created for stock and non-stock/non-file items for vendors who require them. | |||

| N | Y | N |

|

|

|

| Y | Stock items are subject to the response formula, and are placed on a regular PO, if an order is needed. Only stock items are on the PO. Non-stock and non-file items are not combined with stock items on POs. | Stock items are replenished using the Response Formula. If an order is needed, the system creates a separate PO for the stock items, or adds them to an existing PO. Non-stock/non-file items are placed on a separate PO for each department. | |||

| Y | Stock items are subject to the response formula, and are placed on a regular PO, if an order is needed. Only stock items are on the PO. Non-stock and non-file items are not combined with stock items on POs. | If stock items need to be ordered, the system creates a separate PO for the stock items, or adds them to an existing PO. Non-stock/non-file items are placed on a separate PO for each department. | |||

| Y | Y | N |

|

|

|

| Y | Stock and non-stock/non-file items are not combined on POs. | For each department, the system separate POs for stock items and non-stock/non-file items (or adds them to an existing PO for the department.) | |||

| Y | Stock and non-stock/non-file items are not combined on POs. | For each department, the system separate POs for stock items and non-stock/non-file items (or adds them to an existing PO for the department.) |

*On stock items, when not enough on-hand quantity exists to fill a request, the response formula applies. The search for a PO follows the path of organization, vendor/ buy-from location, buyer, and asset location. The department is included in the path since orders for stock items are not tied to a specific department. Therefore, the 'separate PO' flag on any PO that is created is not set to Y.

Copyright © 2023 by Premier Inc. All rights reserved.

requsition requsition reqisition requstion